With the continuous development of the

electronics industry, customers' requirements for product dispensing are

constantly increasing. The dispensing machine is simple and convenient to

operate, which can replace manual work and realize mechanized production. The

dispensing syringe is one of the core accessories of the dispensing machine. In

addition to conventional storage of glue, its role in the dispensing process is

also self-evident.

JDD introduced advanced technology and

equipment from overseas, developed a variety of liquid packaging containers

with international advanced level and sold them all over the world. JDD studied

the specifications of Japanese and American syringes that were popular in the

world at that time for many years. On the basis of absorbing their product

advantages, it also improved their shortcomings and developed a series of

nearly perfect dispensing syringe products, which can not only enable glue

manufacturers to better carry out glue filling production, but also perfectly

match the dispensing equipment in the actual production of end customers, with

accurate dispensing and smooth glue discharge. Since dispensing syringes are so

important and there are so many types of dispensing syringes on the market, the

selection of dispensing syringes is also standardized.

In addition, dispensing syringes are

divided into single-liquid and double-liquid types. When choosing, we should

also consider the properties of the glue, the viscosity of the glue, the

chemical properties of the glue, and the applicable usage scenarios. For

example:

1. Low temperature epoxy adhesive: This product is used for low temperature heat curing and can form the best bonding force between various materials. It improves the product's excellent working performance and has high stability; its use method is also particular: A. It needs to be refrigerated in the freezer, and the storage temperature is 0~-5°C; B. When using, it needs to be placed at room temperature to warm up, and it needs to be prevented from high temperature and used at room temperature; (the general use temperature is 60~80°C.)

2.UV glue: also known as photosensitive glue, ultraviolet light curing glue, is a type of adhesive that must be cured by ultraviolet light. It has strong bonding performance, fast curing speed and is environmentally friendly, so it is highly versatile and has a wide range of applications. UV glue has the fastest development speed in electrical and electronic applications. With the continuous development of science and technology, it has great potential. Application scenarios include: medical supplies, glass and crafts, jewelry industry, electrical and electronic industry, optoelectronics, information industry, etc.

3、PUR hot melt adhesive: Hot melt adhesive is also

called moisture-curing reactive polyurethane hot melt adhesive (PUR); it has

excellent bonding strength, temperature resistance, chemical corrosion

resistance and aging resistance, and most importantly, it is environmentally

friendly; it is now widely used in national economic fields such as packaging,

wood processing, automobiles, textiles, electromechanics, aerospace, etc.

4���、Acrylic structural adhesive: Acrylic structural adhesive is a structural adhesive composed of synthetic acrylate and modified curing agent, and does not require surface treatment. At the same time, it has extremely strong bonding strength, fast curing speed, simple operation and impact resistance. It is widely used in metal, plastic, and composite material shell bonding, such as: laptop computer and mobile phone parts bonding (shell, battery, etc.).

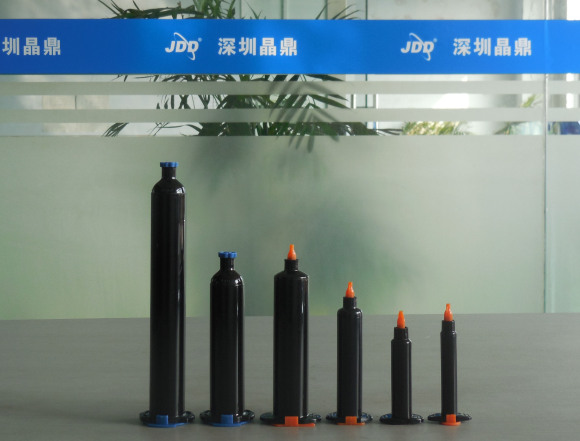

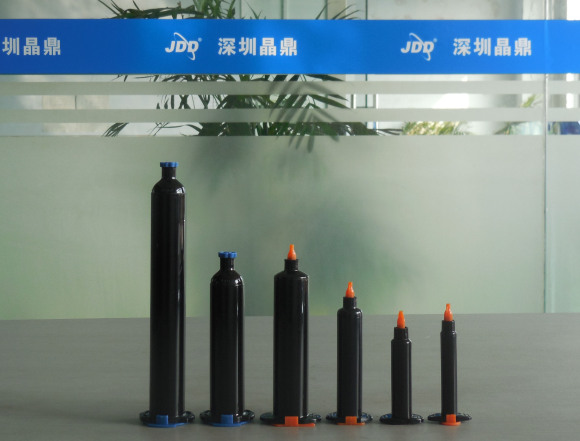

5、300G UV tube: According to different types of glue, it is more effective to choose different types of syringes to ensure the quality of the glue used. The 300CC large-capacity dispensing syringe is suitable for a large number of dispensing operations, reducing the number of times to load glue and improving work efficiency. It can be used directly as a syringe for dispensing glue, and the glue is clean when used. When adding materials, it is necessary to add a feeding nozzle, a pressure regulating device, etc., which is very convenient for adding materials, and the glue position can be visually observed, and it is suitable for various glues.

JDD dispensing syringes are

made of PP material, which is more stable, tougher, and not easily affected by

chemical products; when we use PE pistons with syringes, the double scraper

design can make them fit tightly, ensuring that the liquid is spit out smoothly

without residue. If you need a dispensing syringe, you can go to Shenzhen

Jingding Packaging Materials Co., Ltd. to buy it.

Jingding Company was formerly Chongqing General Plastic Factory, which was established in 1985. It has 30 years of experience in plastic molding. In 2002, Shenzhen Jingding Technology Co., Ltd. was established. In order to adapt to the development of the market, Shenzhen Jingding Packaging Materials Co., Ltd. was established in 2007. During this period, it created its own brand, JDD, and quickly developed into the first brand in the domestic dispensing industry.

Jingding Company specializes in the research and development, production and sales of dispensing equipment and dispensing consumables. It is the first manufacturer in China to set up a professional R&D department, technical department, and mold department. All products are independently developed, designed, molded and injected, and have won many product patent certificates; the process operation is rigorous, and the key performance of some products is world-leading, surpassing the United States and Japan.

Jingding Company also has a strong sales team and a very advantageous price-performance ratio. It is currently the supplier of dispensing consumables with the highest market share in China. The company has been recognized by the industry for its integrity, strength and product quality. Friends from all walks of life are welcome to visit, guide and negotiate business. For more information on dispensing consumables, please pay attention to us!